MEG Energy Corp

TSX:MEG

| US |

|

Johnson & Johnson

NYSE:JNJ

|

Pharmaceuticals

|

| US |

|

Berkshire Hathaway Inc

NYSE:BRK.A

|

Financial Services

|

| US |

|

Bank of America Corp

NYSE:BAC

|

Banking

|

| US |

|

Mastercard Inc

NYSE:MA

|

Technology

|

| US |

|

Abbvie Inc

NYSE:ABBV

|

Biotechnology

|

| US |

|

Pfizer Inc

NYSE:PFE

|

Pharmaceuticals

|

| US |

|

Palantir Technologies Inc

NYSE:PLTR

|

Technology

|

| US |

|

Nike Inc

NYSE:NKE

|

Textiles, Apparel & Luxury Goods

|

| US |

|

Visa Inc

NYSE:V

|

Technology

|

| CN |

|

Alibaba Group Holding Ltd

NYSE:BABA

|

Retail

|

| US |

|

3M Co

NYSE:MMM

|

Industrial Conglomerates

|

| US |

|

JPMorgan Chase & Co

NYSE:JPM

|

Banking

|

| US |

|

Coca-Cola Co

NYSE:KO

|

Beverages

|

| US |

|

Realty Income Corp

NYSE:O

|

Real Estate

|

| US |

|

Walt Disney Co

NYSE:DIS

|

Media

|

| US |

|

PayPal Holdings Inc

NASDAQ:PYPL

|

Technology

|

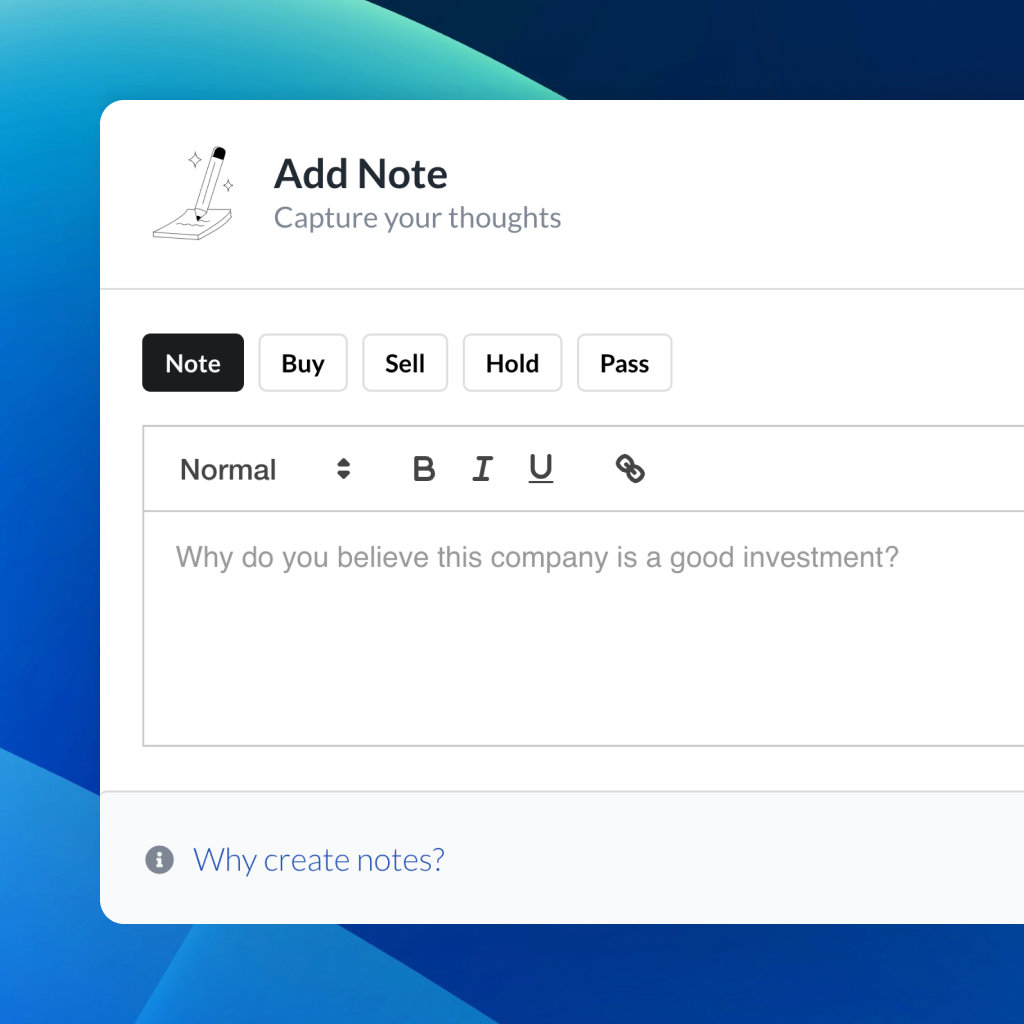

Utilize notes to systematically review your investment decisions. By reflecting on past outcomes, you can discern effective strategies and identify those that underperformed. This continuous feedback loop enables you to adapt and refine your approach, optimizing for future success.

Each note serves as a learning point, offering insights into your decision-making processes. Over time, you'll accumulate a personalized database of knowledge, enhancing your ability to make informed decisions quickly and effectively.

With a comprehensive record of your investment history at your fingertips, you can compare current opportunities against past experiences. This not only bolsters your confidence but also ensures that each decision is grounded in a well-documented rationale.

Do you really want to delete this note?

This action cannot be undone.

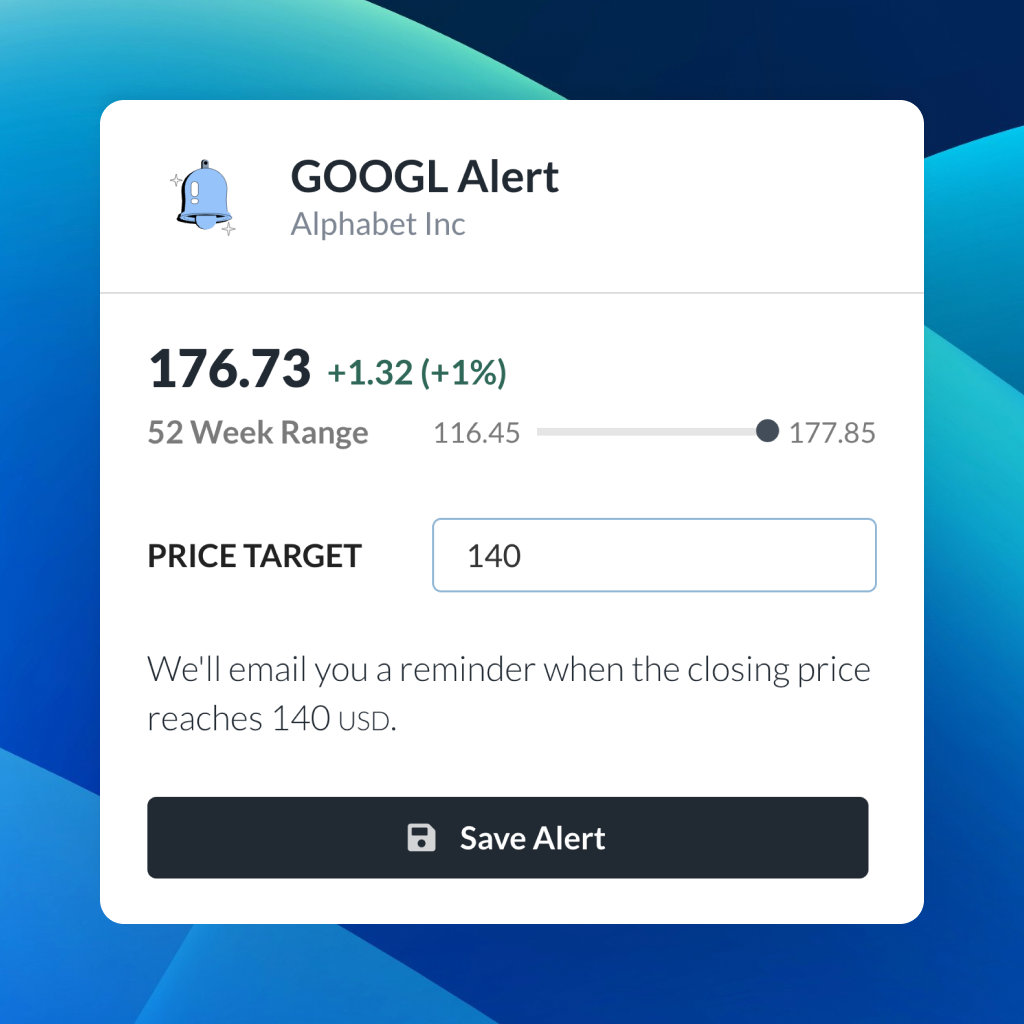

| 52 Week Range |

22.67

33.43

|

| Price Target |

|

We'll email you a reminder when the closing price reaches CAD.

Choose the stock you wish to monitor with a price alert.

|

Johnson & Johnson

NYSE:JNJ

|

US |

|

Berkshire Hathaway Inc

NYSE:BRK.A

|

US |

|

Bank of America Corp

NYSE:BAC

|

US |

|

Mastercard Inc

NYSE:MA

|

US |

|

Abbvie Inc

NYSE:ABBV

|

US |

|

Pfizer Inc

NYSE:PFE

|

US |

|

Palantir Technologies Inc

NYSE:PLTR

|

US |

|

Nike Inc

NYSE:NKE

|

US |

|

Visa Inc

NYSE:V

|

US |

|

Alibaba Group Holding Ltd

NYSE:BABA

|

CN |

|

3M Co

NYSE:MMM

|

US |

|

JPMorgan Chase & Co

NYSE:JPM

|

US |

|

Coca-Cola Co

NYSE:KO

|

US |

|

Realty Income Corp

NYSE:O

|

US |

|

Walt Disney Co

NYSE:DIS

|

US |

|

PayPal Holdings Inc

NASDAQ:PYPL

|

US |

This alert will be permanently deleted.

MEG Energy Corp

MEG Energy Corp

You don't have any saved screeners yet

You don't have any saved screeners yet

Good morning. My name is Pam, and I'll be your conference operator today. At this time, I'd like to welcome everyone to the MEG Energy 2020 Third Quarter Results Conference Call. [Operator Instructions] Mr. Derek Evans, CEO, you may begin your conference.

Thank you, Pam, and good morning, everyone, and thank you for joining us to review MEG's Q3 2020 operating and financial results. With me this morning is Eric Toews, our CFO; Chi-Tak Yee, our Chief Operating Officer; and Lyle Yuzdepski, our General Counsel and Corporate Secretary.Just a reminder that this call contains forward-looking information, please refer to the advisories in our disclosure documents filed on SEDAR and on our website. MEG continues to proactively respond to the safety and financial challenges associated with the COVID-19 pandemic. I'd like to take a second to express my sincere appreciation to all our staff for what they've done and what they continue to do to ensure the health and safety of their teammates as well as the safe and reliable operation of the Christina Lake facility throughout this pandemic period.Highlights in the quarter include: successful completion of the planned 75-day major turnaround, on time and under budget; continued reduction in nonenergy operating costs and G&A expenses; post turnaround production exceeding earlier estimates; the addition of 2020 second half WTI hedges to ensure successful completion of the 2020 capital program without drawing the revolver; and continuing to build the cash on hand at year-end to help fund our 2021 capital program.As we head into year-end, we're increasing annual production guidance, decreasing annual G&A and nonoperating guidance and expect to build free cash flow through the balance of the year with 80% of our fourth quarter WTI sales exposure hedged at approximately USD 46 per barrel. We remained well positioned from a financial liquidity perspective, benefiting not only from our significant 2020 hedge book and the term and structure of its outstanding indebtedness and credit facility, but also from the low decline and low cost of the high -- cost structure of the high-quality Christina Lake asset.I'd like to touch on some of these financial and operating highlights of the third quarter in greater detail. MEG realized an average AWB blend sales price of USD 34.13 per barrel during the third quarter of 2020 compared to USD 15.12 per barrel in the second quarter of 2020. MEG sold 62% of its sales volumes to the U.S. Gulf Coast in the third quarter of 2020 compared to 35% in the second quarter of 2020. This increase in sales to the U.S. Gulf Coast in the third quarter of 2020 is primarily as a result of the corporation's increased contracted transportation capacity on the Flanagan South/Seaway pipeline systems effective July 1, increasing from 50,000 barrels a day to 100,000 barrels a day.Transportation and storage costs averaged USD 10.07 per barrel of AWB blend sales in the third quarter of 2020 compared to $5.92 per barrel in the second quarter of 2020. The increase in transportation and storage cost is primarily due to the fixed costs associated with the increased Flanagan South/Seaway contracted capacity and lower apportionment on the Enbridge Mainline. The additional transportation capacity afforded by the higher contracted capacity and lower apportionment was underutilized by MEG during the third quarter due to the planned turnaround. Subject to the actual level of apportionment on the Enbridge Mainline system, transportation costs are expected to average between USD 7.50 and USD 8.50 per barrel of AWB blend sales through the remainder of 2020 and 2021. Bitumen production averaged 71,516 barrels per day in the third quarter of 2020 compared to 75,687 barrels in the second quarter. Bitumen production in the third quarter of 2020 was impacted by major planned turnaround activities at the Phase 1 and Phase 2 facilities, which began in early June and were completed in mid-August 2020. The 2020 turnaround was extended in duration to 75 days, expanded in scope relative to base budget in order to minimize staff levels at site during COVID-19 and maximize utilization of MEG's internal resources, thereby lowering overall cash costs. MEG also made the decision to advance turnaround activities from 2021 to significantly reduce the '21 turnaround requirements. Turnaround was completed on time and under budget with post turnaround production exceeding guidance. Notwithstanding multi-decade low crude oil prices, MEG generated $85 million of free cash flow in the 9 months ended September 30, 2020, and exited the third quarter of 2020 with its credit facility undrawn and $49 million of cash on hand. For the fourth quarter of 2020, MEG has entered into benchmark WTI fixed price hedges for approximately 80% of forecast bitumen production at an average price of USD 45.76 per barrel. Based on better-than-expected production performance during the post turnaround -- during and post turnaround, MEG is revising upward its full year 2020 average production from 78,000 to 80,000 barrels a day to 81,000 to 82,000 barrels a day.G&A expense is now targeted to be in the range of $45 million to $47.5 million or approximately $17.5 million lower than original guidance. Nonenergy operating costs are now expected to be in the range of $130 million to $135 million or approximately $32.5 million lower than original guidance. Of the $50 million aggregate reduction in expected costs, approximately $22 million are the result of temporary cost reductions while the remaining $28 million in cost reductions are the result of continued optimization of operations, reduction in staffing levels and rationalization of ongoing administrative costs.Finally, the consolidation theme has been front and center with a number of transactions announced in the U.S. and the notable transaction announced earlier this week in Canada between Cenovus and Husky. The consolidation theme is something that MEG is familiar with, and we manage our business to best ensure that we're on our front foot from a transaction perspective and not vulnerable to market dislocations, disadvantaging MEG shareholders. As it relates to oil price volatility, which has been a stated driver of recent transactions, we maintain a constructive view on WCS volatility go forward as we are seeing positive progress on both Enbridge Line 3 expansion expected to be in service in the second half of 2021 and the TMX expansion expected in 2022. We have 20,000 barrels a day of blend capacity on TMX. And as you know, we have a 100,000 barrels a day of capacity on Flanagan South/Seaway. Anecdotally, we see the Alberta government's elimination of curtailment as further evidence of the positive momentum for light-heavy differentials and WCS pricing. With respect to the benchmark WTI pricing, MEG has been relatively successful in protecting cash flow through significant WTI hedges in 2020, allowing for the repayment of $130 million of long-term debt as well as the building of free cash flow through 2020. We are continuing this hedging discipline as we move into 2021 with approximately 25% of expected sales hedged at around $46 WTI, and we look forward to adding more hedges as the opportunities present themselves. Our modified covenant-lite revolver remains undrawn, is in place until mid-2024. And our first long-term debt maturity isn't until early 2024, providing us with financial breathing room as we navigate through COVID-related impacts.MEG expects to release its 2021 capital budget in early December. While development of the 2021 capital budget remains in progress, it will be designed to be fully funded with internally generated funds. This is consistent with MEG's financial discipline in 2020, where the current year's capital program remains on track to be fully funded with internally generated funds.Finally, we have an industry-leading cost structure, taking G&A down by $35 million since I joined MEG in 2018, and our nonenergy operating costs remain best-in-class. Once the Cenovus-Husky transaction is complete, MEG will be the only pure-play SAGD producer of scale, and we will continue to run our business on our front foot in the best interest of all shareholders.With that, I will turn the call back to the operator for questions.

[Operator Instructions] Your first question comes from Phil Gresh with JPMorgan.

First question was, Derek, on the last call, you talked about a $250 million sustaining capital number to maintain production in kind of 80,000 to 85,000 barrels a day range, I believe. It looks like the fourth quarter number, the implied guidance is at least at those types of levels coming out of the turnaround. So I was just wondering how you think -- do you have any adjustments to that thinking as you enter 2021 about what kind of production you can maintain and then what kind of capital have you acquired?

Phil, thanks for the question. As we think about 2021 at this point, I think we're thinking of our capital number in that $200 million to $250 million range. It's still being worked by our technical staff. And so I don't think that's really changed since we would have last talked to the market on that. With respect to what the production number is, I think that we're still working through, I'd say, some flush production associated with the turnaround. Our production is higher than the 85,000 barrels a day that we projected that it would be, coming out of turnaround. So we're not ready yet to comment on what the production profile is going to look like next year.

Okay. Okay. Fair enough. And just any other thoughts on costs as you enter 2021, whether it's nonenergy OpEx or just the G&A. I know you mentioned that some of those G&A savings were temporary. But if we continue to be in a challenged pricing environment with WCS kind of around $30, how you'd manage those costs?

Phil, so fundamentally, we manage costs day in, day out, whether we're in a COVID or in a low-price or a high-price environment. So I think we've done a reasonably good job pointing out the cost, which would be fundamentally nonrecurring. And I think on the operating side, we're pointing to $15 million. And on the G&A side, we're reporting $7 million. But I don't think people should take away from that, that we're going to be -- we're not going to continue our ongoing work on continuing to reduce G&A and operating cost to the best of our ability each and every day.

Your next question comes from Phil Skolnick with Eight Capital.

When I get 2 Phils back to back. So any -- just a couple of questions. First of all, any kind of -- any update? You had talked about, I can't remember if it's the last conference call or the prior conference call before that, potentially looking at using different types of diluents to reduce your diluent need going through the Access Pipeline.

Phil, I was going to say Phil 2, but that is inappropriate. Thanks for the question. What we've been talking about is a proprietary process that would -- we had hoped to have up and running in a significant way that there was some new technology that we bolted into Christina Lake that had significant potential to reduce our diluent requirements on a go-forward basis. That equipment is being commissioned as we speak, and we hope that over the next couple of months, we're going to start to see whether the bench scale testing that was done showed a significant reduction in the requirements of diluent to meet pipeline viscosity actually is borne out in the field.

Okay. Is this something you're working in conjunction with CNRL?

No. We're working with the company that has put this technology forward.

Okay. And then just a final question. Just on the -- during the turnaround because it was 75 days. I mean, it was because trying to manage around the COVID risk. But given that you did have that extra time to use, was there anything that you discovered, maybe any more debottleneck opportunities or anything like that?

I don't think there was anything that came out of that in terms of debottlenecking activities. I think we were generally pleased with the state and the condition of the equipment that we saw as we got in and looked at those things, but nothing from a debottlenecking process. And I should basically say, debottlenecking is an ongoing sort of exercise with our facility. So I guess, I would have been surprised if anything unusual had come up in the process as it's a fairly continuous exercise that goes on through on a day-to-day basis.Phil, just before you go, I think what you may have been referring to was our butane-blending operation with CNRL. So that butane-blending project is moving forward, and we expect to have it in -- up and operating sometime in the New Year.

[Operator Instructions] Your next question comes from Neil Mehta with Goldman Sachs.

We know it's early out there in Calgary. The first question I had was just around WTI breakeven as you think about 2021. Where do you see that, Derek, on a U.S. dollar basis to cover growth in sustaining CapEx next year?

Neil, great question. And don't worry about us getting up early, we're used to that. The breakeven for -- from a WTI perspective is typically, I'm going to say in that mid-40s type range. And that's with what I would call a fairly conventional sort of WTI:WCS differential. As you've heard on the call, we are -- we believe that the WTI:WCS differential is actually in the process of shrinking as more pipeline capacity becomes available. And we're very encouraged about the movement that we've seen in that regard and what that does for the long-term prospects for somebody like ourselves, which is a pure-play WCS player. So you did -- it's in that $45 range.

And that's at the $200 million to $250 million of CapEx?

Yes.

Okay. And then if I can sneak in 2 questions, and maybe you can comment on both quickly because I think your comments on M&A were intriguing. Certainly, it's been a big focus here in North America over the last week. Just what role do you see MEG playing in consolidation over time?And then the other is, I'd just love you to flesh out your thoughts on WCS a little bit more here. It sounds like you've got a more constructive view. There are some who think that light-heavy will widen out because of incremental barrels coming out of the market in Canada. So your perspective on both of those would be awesome.

So just on consolidation, we don't see ourselves being a driver in the consolidation business. We're just going to continue to operate our business, focus on reducing our op costs, our G&A costs and being sort of the premier low-cost, pure-play WCS producer with a 60-year reserve life. So I'm sorry, I can't tell you anything more exciting than we're going to just continue doing what we've been doing for the last 10 years. On the second part, which was really we appear to be or sound to be more constructive than others, maybe in terms of the WCS:WTI differentials. We would point to the fact that storage levels in the province in Alberta are at some of the lowest that we've seen historically. We've seen continued small improvements on both the Enbridge system and on the Keystone system. We've got the Northwest upgrader actually running and processing heavy. All 3 of those add somewhere in the neighborhood of 150,000 barrels a day of incremental demand. We're seeing unprecedented levels of interest in our heavy crude in the U.S. Gulf Coast, not only for U.S. Gulf Coast refineries, but -- and in the Caribbean as well as -- obviously, you saw the Reliance deal and that product moving to India. So we think there's been a step rate change even before you start to consider the Enbridge line 3 project, which -- replacement and expansion, which should come on in mid-2021. And it's surprising to us, but people continue to still think that TMX isn't going to get built, even though there's numerous pipeline spreads out with pipeline in the ground. And as we pointed out here again today, I think people have forgotten that we have 20,000 barrels a day of long-haul capacity. So I think directionally, we're back in a position where pipeline capacity, egress capability is not going to be as big a problem as it has been in the past. That should be reflected in the differentials. And that really is our thesis on why we believe there has been a step rate change, and that's very positive for our business, obviously.

Your next question comes from Greg Pardy with RBC Capital Markets.

So Derek, a couple of things. The CapEx range you're mentioning here of $200 million to $250 million. And I think the last number I recall, you guys talking about was more like $250 million. But again, if it's equipped to deal with all the sustaining initiatives, have you found additional ways to essentially reduce your sustaining costs? Is that embedded in that? Or is the number just not really to work at this stage?

The number is a fluid number. And when I talk about $200 million to $250 million, I'm also talking -- we -- our -- any capital program is going to be cash-based. So for whatever reason, if we see crude drop to a lower level than sort of that $45 level that we would hope that it could average, we're going to have to pull back on our capital. And so I probably didn't explain that well in terms of that, that range is really predicated on cash being available. But to fully sustain production next year, we need approximately $250 million.

Okay. Okay. And I think aside from being the only pure player or will become the only pure-play oil sands producer, you guys are also quite advanced when it comes to solvents. Could you maybe just remind us or just bring us up-to-date as to how the eMVAPEX program is working and perhaps what you've seen in terms of reduced SORs and so on?

I'm going to ask Chi-Tak Yee to -- our Chief Operating Officer and really our -- the primary -- or the principal behind this whole project to provide that update.

Thanks, Derek. Yes. So as you know, we have these eMVAPEX pilot that's been on close to 3 years now. And just to remind everybody, that's the one that we use propane instead of steam into the reservoir to reduce the viscosity of the oil so that it can produce at a lower energy intensity. The process is actually working quite well. We have actually subdivided the pilot into 2 pilots so that we can test different aspects of the process. So far, we're seeing a very good reduction in steam-oil ratio. In fact, in some cases, we're trending essentially zero. We inject just pure solvent without any steam injection at all. So that from a steam-oil ratio point of view pulls up quite well. What we need a bit more time is to understand more on the bitumen recovery end of it. As you know, the well life of this well was typically 10-plus years. And so we are relatively early into the -- understanding the bitumen recovery aspect of it. And also another very important economic driver is the solvent recovery, how much solvent do you recover from the process. And that one, by and large, it checks out quite well. We're having a very good recovery of the solvent from the reservoir. So like I said, the remaining point here now is try to figure out what happens to the bitumen recovery itself, and that's where we are today.

Okay. And then -- so you mentioned you've broken the pilot into 2 -- segregated into 2 pieces. Are you seeing similar results from both? Like what's the difference between the 2?

The first pilot was -- involved the safety well, but that turned on earlier. So it's more advanced in its safety process before we implement the solvent. And then the -- also the later pilot involved -- as you recall, we actually built a solvent recovery facility for the bigger pilot so that we can reduce the overall cost of the pilot by recycling as often as possible. So the second pilot has a more complete test of the whole package that includes almost a simultaneous injection of solvent at the same time on all the wells as well as testing the recycled aspect of it from a surface acidity point of view.

Okay. Last 2 for me because we'll move on. But can you -- what -- industry averages, I think, in terms of recovery rates are mid- to high 50s, I believe. But can you maybe confirm or deny or indicate whether that's a good range or not for the industry? And where would you guys be stacking up?

I imagine you're referring to solvent recovery. Is that your question?

No, it's more on the recycling. Recycling, I thought was actually lower than what people were targeting, but...

Yes. So there are 2 -- yes, 3 recoveries. There's a bitumen recovery we already talk about, and there's a solvent recovery from the reservoir and then the third one is once we recover the solvent from the reservoir, how much of that you can actually recycle and put back to the reservoir, okay?

Okay.

So from a reservoir, from the recovery of solvent, from a reservoir point of view, we're doing quite well. I can't give you a pretty specific number, but it's north of 70%. So which means you inject a barrel of solvent into the reservoir, you get at least 70% of that back. And then the other aspect is once we get this solvent back, as we got contaminants in it, methane and other molecules in it, so the recovery efficiency of that is close to about 90%. Does that answer your question?Did we lose him?

Yes, it looks like he's no longer in the queue. So I believe you must have answered his question.

All right. Okay.

And Mr. Evans, there are no further questions at this time. You may proceed.

Well, listen, thank you all to everybody that joined the call this morning. It was an early morning. Appreciate your interest, and please don't hesitate to follow up with either Eric or myself with any further questions you might have with respect to the specifics of the quarter. Thank you for your time today.

Ladies and gentlemen, this concludes your conference call for today. We thank you for participating and ask that you please disconnect your lines. Have a great day.